Prototyping

Prototype Development

Our prototyping machinists and tool makers can turnaround high precision projects in two weeks or less. With a combined experience of more than 100 years in product development, CIMtech Mfg capabilities can fill your Prototyping needs, from concept to completion in virtually any material including fabrication & sub-assemblies.

As a progressive Machine Shop we can machine your Prototypes directly from solid models without the need of detailed drawings or step models.

In house engineers and machinists will constantly evaluate your manufacturing designs and tolerances providing a feedback program like no other, which entail helps on lowering the cost of manufacturing.

Working closely with our clients we can quickly and efficiently report any dimensional errors or inconsistencies by reviewing tolerances, moving you closer to production ready.

CIMtech will provide complete start to finish turnaround on your parts, including secondary processes such as: Anodizing, Zinc Plating, Black oxide, Powder Coating, Painting and Penetrate Inspection

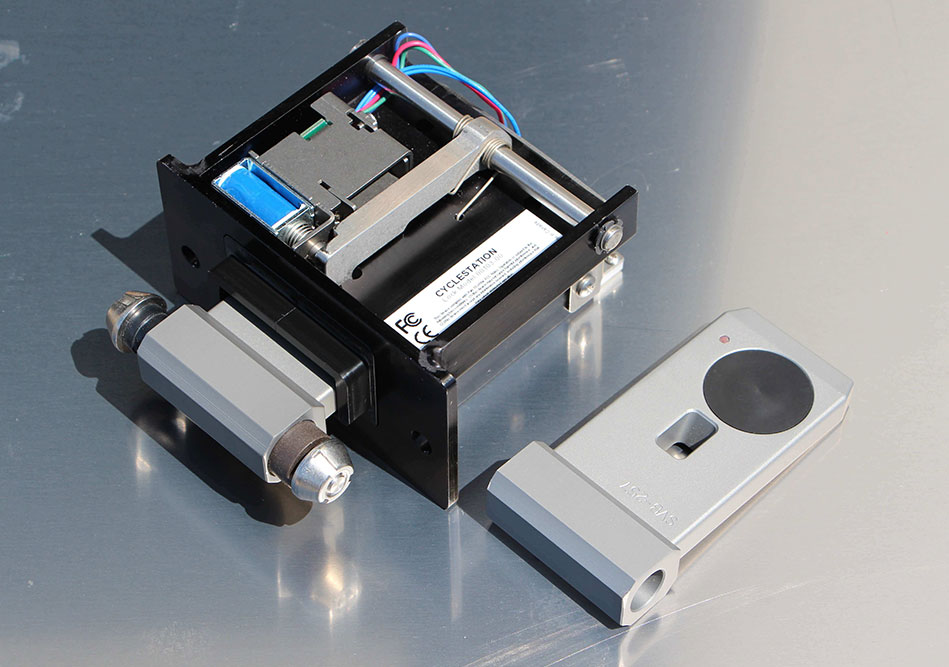

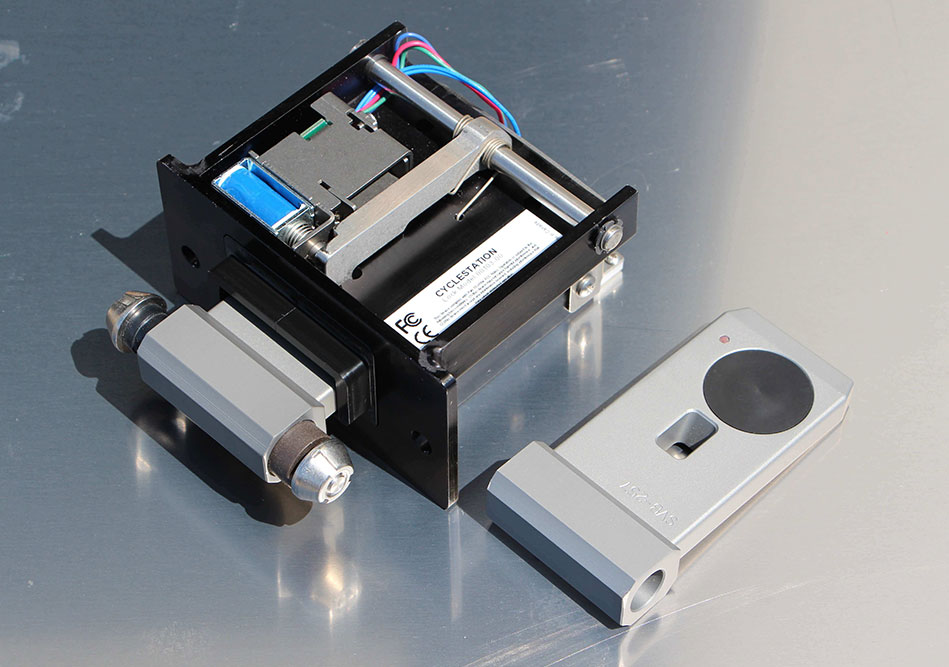

Testing prototype

Prototyping Bike Share

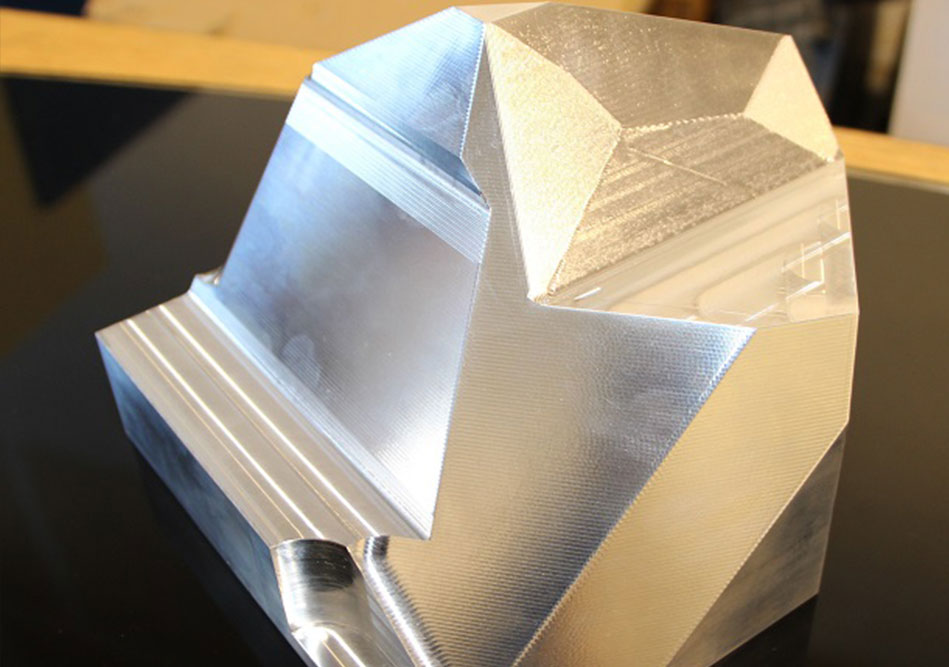

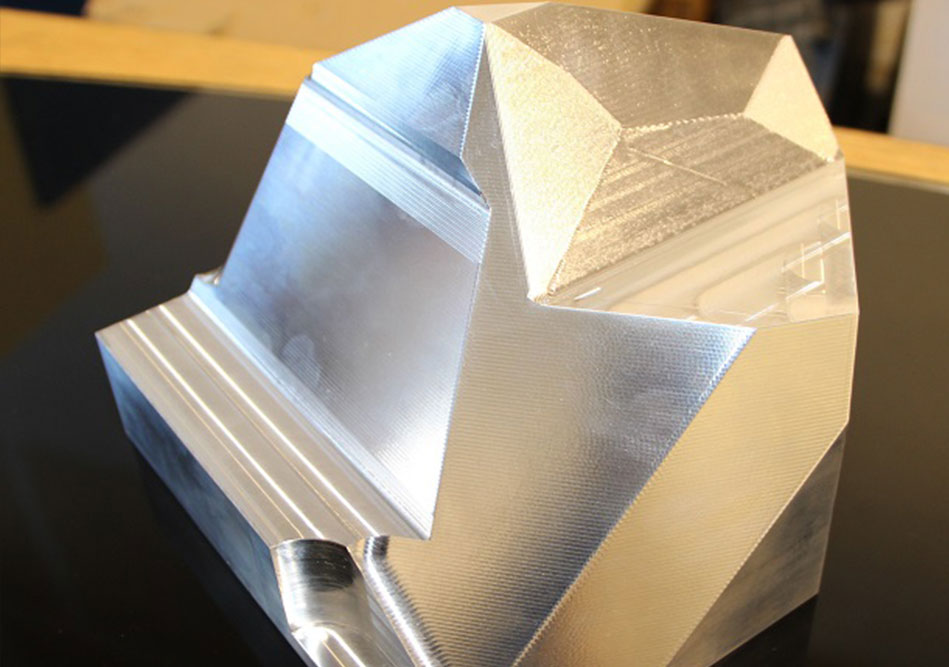

Prototype from Solid block

Jigs & Fixtures

Stainless Steel

Plastic Prototyping

Assorted Prototypes

Stator Prototype (Finishes)

Prototypes in 7 - 10 days.

CIMtech have been diligent in pointing out machining issues on our parts designs. They have one of the best CNC machining facilities in BC. I am happy to recommend their manufacturing engineering services.

Emilie

Project Manager